The clouds gathered in the dark sky and weighted my heart. An electrically charged silence filled the

room as if the storm was going to ignite inside the house. I looked around like knowing my worst

fears were ready to raid. A violent flash told me that the storm would not be around much longer.

The growl of thunder penetrated deep into my heart. I knew, this wasn’t the moment I wanted to

experience. For to many years I have chosen to postpone this. Fleeing for the inevitable moment

where I was heading for at fast speed. It was clear for me that I could no longer run away from my

destiny. I straightened my back and took a deep breath. It was time to face the painful truth.

Luxpen

laurent@luxpen.be – https://www.luxpen.be

Instagram: @luxpenlaurent

Facebook: Luxpen

Background on the maker

Let me introduce you to Laurent d’Haeseleer, who has been a teacher in arts education for 30 years. After his teaching years he was a coach in personal development for 15 years.

During his time as teacher he developed an interest in origami. After 20 years he reached the top and he was recognised throughout the world. He spoke on several international conferences and was able to get some great Japanese Masters to discuss and show their skills in Europe. About 10 years ago, Laurent went from paper to wood. He started woodturning and followed several classes in Germany to learn how to make a reliable pen. Besides pens he also makes pepper, salt and nutmeg mills, is an official retailer for Diamine inks and he likes to play golf.

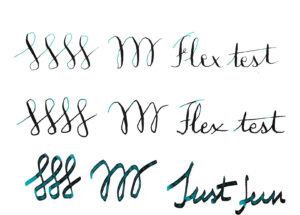

Materials and specialties

Laurent has a passion for wood. He is always on the lookout for new kinds of wood to work with. This goes from more common kinds like Nogal and Olive to African hardwood or unique pieces that made part of a film decor. Besides wood he also works with leather, carbon, ebonite and other blanks like Conway Stewart or DiamondCast®.

For different pens you can find the story or additional information on the wood in the description of the pen on his website. For me this is a proof that Laurent’s passion. He’s not selling just pens. He does his research, he wants to educate other people and he clearly chooses his materials.

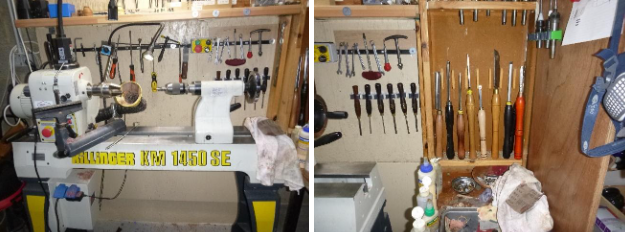

As Laurent does make pens as a pastime he invested only in a simple lathe for wood turning. All metal work and mechanisms are purchased.

Turning to life

As the metal parts are bought, there is less freedom in creating the pens. Laurent works with 6 models of fountain pen, 4 types of roller pen and 3 types of ballpoint pen. Each model can be done in different kinds of wood or other material. The more rare materials are kept exclusively for the Prestige model.

The turning of the wood is done rather old school. Pure craftsmanship, no CNC. This means that each piece is turned in different stages. Measuring the dimensions after each stage.

After the right dimensions are reached, the pieces are sanded to the required smoothness.

For Laurent pen and mill turning is all about solidity, durability, quality and precision.

Production quantities and customers

Notwithstanding the short period of wood turning, Laurent was rather fast recognised as an official craftsman in January 2017. Due this title he got a rather big assignment a few years ago to make the fountain pens for the official ceremonies of the government. This means that his pens were given to all prominent international guests like ambassadors, members of foreign government, …. Due to the requested high volume Laurent had to call in the help of some friends and managed to deliver.

Nowadays the volume is back to normal and Laurent produces about 50 pens a year. Most customers find him via local craftsmanship fairs, his website, the media/newspapers and via the list of recognised craftsman/woman of the Belgian Federal Public Service for Economy .